Table Of Content

One of the issues with using this formula is that while DFU is a common term for plumbers, it is uncommon for pretreatment coordinators and officials dealing with the regulation of GGIs. Also, the DFU does not differentiate between flow from a fixture and flow from a draining sink. When plumbing fixtures do not drain from filled sinks, the faucet flow is used; however, when a filled sink drains, Manning’s Equation should be used to determine the peak allowable flow. The 1980 version of the EPA formula, which is still used today, calculates the influent flow rate as 5 gallons per meal.

Learn How To Design A Grease Trap Like A Pro! Simple Steps To A Cleaner Kitchen

This comprehensive guide will provide a step-by-step approach to designing grease traps, empowering you with the knowledge to create effective and compliant systems. Precast concrete GGIs not only provide greater storage capacity and longer retention times, but also offer the added benefits of structural integrity, design flexibility and a long service life. Outdoor concrete interceptors provide a level of health safety by removing this process from the food preparation environment.

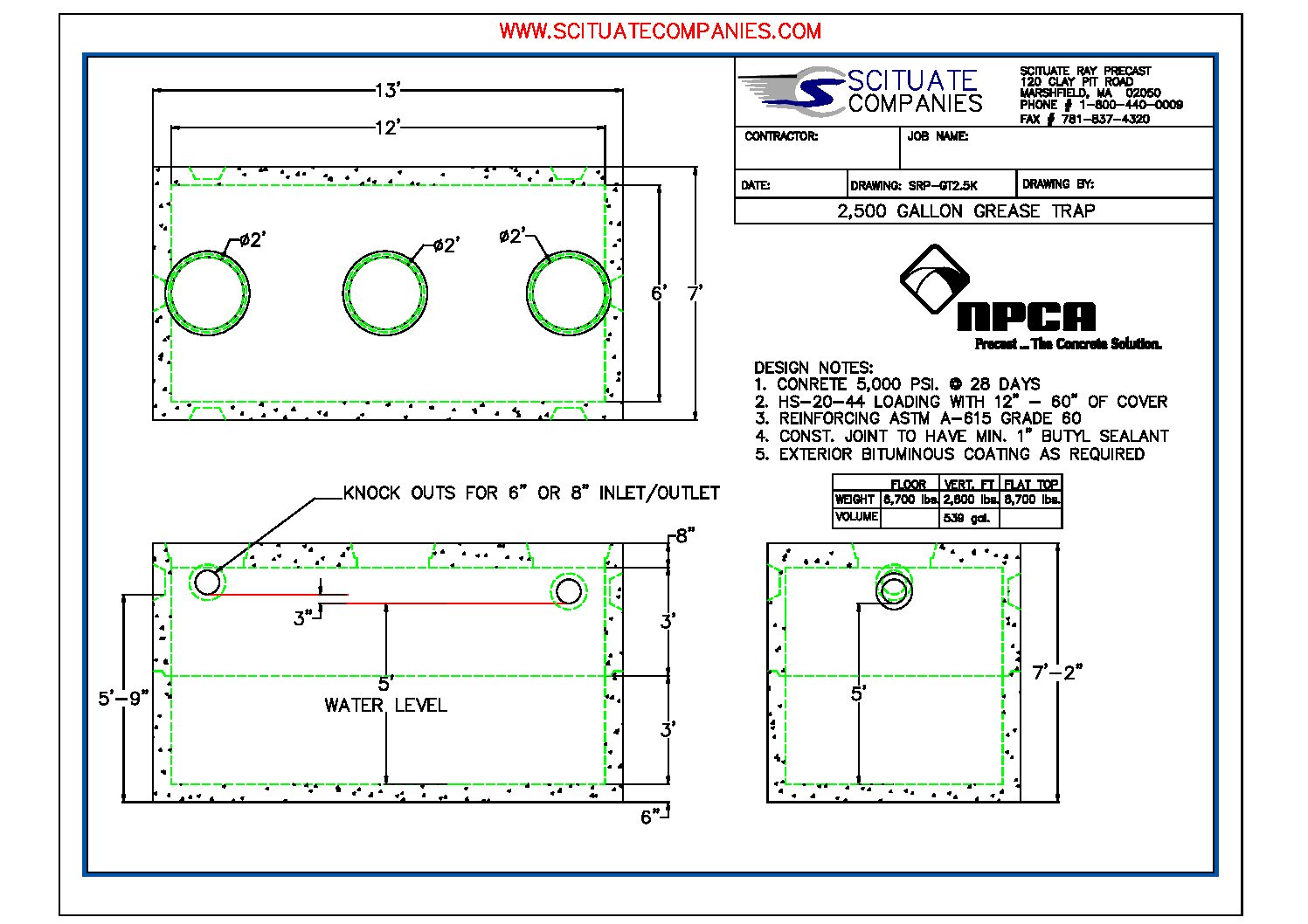

CAD Drawings for Grease Traps

Tim Hortons grease trap: The untold story on Bryce Raynor's death - Democrat & Chronicle

Tim Hortons grease trap: The untold story on Bryce Raynor's death.

Posted: Wed, 25 Sep 2019 07:00:00 GMT [source]

Our grease interceptor sizing maximizes efficiency and ensures adequate grease retention capacity. With customized sizing from us, establishments can maintain problem-free drains and plumbing while meeting all code requirements. Oil and grease traps intercept and separate most greases and oils before they enter the wastewater collection system.

Factors to Consider in Grease Trap Design

However, the short-term impact of this density upflow is minor on the effluent FOG concentration. Over time, the effluent FOG concentration will be similar to previous uniform influent/bulk temperature results. If the density of the globule is less than the density of the fluid, the globule will rise at velocity V, and vice versa. If we were to divide that globule size in half to 100 microns (.00033 feet), the globule would rise at 0.002 ft./s. Therefore, for more effective separation, larger grease globules are optimal. The right sizing helps prevent sewer line clogs, equipment damage, and fines for non-compliance.

Wrap-Up: Empowering Effective Grease Trap Management

Neville Engineering manufactures highly durable and long-lasting oil and grease separators. These separators can withstand the harshest environmental conditions and heavy usage in various industries. They prevent clogs and blockages in piping that can lead to wastewater overflows and backups. Grease traps have baffles and flow control fittings that retain the grease in a reservoir while allowing the greywater to flow to the wastewater system.

Our Process

Neville Engineering’s separators require minimal maintenance, ensuring longevity and reliable performance for years. We use proven systems to provide effective solutions, avoiding costly experimental designs. Identify the optimal location for the grease trap, considering flow patterns and ease of access for cleaning.

For the above formulas, calculations are performed based on the following scenario. FOG is removed from dishware during cleaning and interacts with excess cleaners and sanitizers to begin saponification, the process that produces soap. Prevent clogged and blocked drains – Our traps catch grease before it coats and sticks to piping.

Stop Clogging With Stellar Interceptor Design

Applying this to XYZ Restaurant, the flow rate would drop to below 20 GPM, thus requiring a 750-gallon tank. Bring your commercial or multi-family building plans to life with Neville Engineering Service, Inc. Our experienced team provides expert heating, ventilating, air conditioning, plumbing, and electrical services to perfect your building’s performance. Our grease traps incorporate green technology, such as recycled steel content and energy-efficient manufacturing methods. Do not purchase a grease interceptor without obtaining a building plan approval including an Industrial Waste approval letter specifying the size and design of the interceptor that will be required. Purchasing an interceptor prior to IW approval exposes the purchaser to risk of rejection and replacement costs.

Why Choose Neville Engineering Oil and Grease Trap Designs?

However, these requirements also allow larger HGI models if site conditions are not ideal for a Gravity Grease Interceptor. We begin with an initial consultation where we discuss your project requirements and expectations. This helps us gain a clear understanding of your goals and enables us to propose the most appropriate design solutions. For intermittent flow into the drainage system, DFUs can be calculated based on the rated discharge capacity in GPM using Table 702.2(b) of UPC Chapter 7 (Table 4). In deciding what formula to adopt, the authority having jurisdiction should ensure the formula is clear so that the assumptions behind the flow calculations are known.

Prevent corrosion – Grease is acidic and can eat away at plumbing and sewer infrastructure if left uncontrolled. The goal for engineered GGIs is to closely comply to the concrete GGI requirements but allow slight flexibility if site conditions are not ideal for a concrete GGI. If DFUs are not known, Table 702.2a of UPC Chapter 7 (Table 3) can be used to assign values based on the maximum DFUs allowed for the pipe size connected to the inlet of the interceptor.

Ideally, the area would occupy the entire cross-section of the of the grease interceptor (i.e., depth times height), as this setup would provide the lowest fluid velocities. To achieve this, the influent baffle would have to be designed to distribute the incoming flow (Figure 3). Grease interceptors work to remove FOG and other materials through separation by gravity or flotation.

As a technology-driven company, we pride ourselves on leveraging proven strategies to deliver advanced, high-efficiency grease traps. We use simple, tried-and-true solutions to drive success and promote comfort, flow, and life throughout your building. Our MEP services prioritize energy efficiency and everyday use, so you never need to think about your plumbing system. However, the white paper did not include any data from the WERF studies mentioned above. As such, until further research is conducted, there is no “right” or “wrong” formula to use.

This may work in some situations, but information is being left out of this calculation that may lead to a tank too small or too large for the application. Create detailed design drawings and specifications for the grease trap, including dimensions, materials, and installation requirements. Choose the appropriate grease trap type based on the flow rate and available space. Determine the size of the trap using the grease retention capacity calculated in step 1. We offer a wide range of comprehensive services to cater to all your GREASE TRAP design needs. From initial concept development to detailed design drawings, we handle every aspect of the process with precision.

No comments:

Post a Comment